Hi all --

Just wanted to share today's DIY project which I managed to finish in 2 hrs, all while wearing a respirator (my lungs can't handle more than 2 hrs at a time). Maybe this will be useful to folks who live in rented flats but still want to have a working distributed air ventilation w/o losing their security deposit.

[I am at the end of my 3d week on Xolair. I have had, maybe, 3-4 "good" days in the last 3 weeks, but overall I am still disabled. 1.5 years ago I could run a hilly marathon, and now I cannot spend more than 2 hrs doing regular house work (my lungs feel "tired of breathing"). Not sure what I will do if Xolair does not work. I can make it through the day working on my PC, but any extra effort (talking or walking) is a problem.]

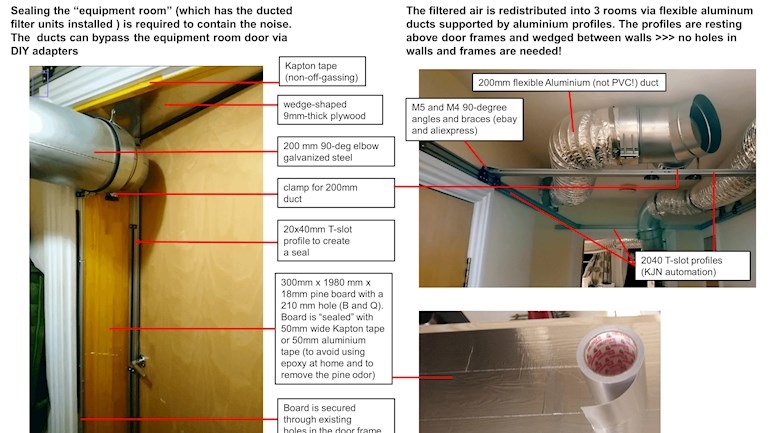

Sorry, got side-tracked. Back to the DIY. For the last 4 months, I have been living in a pressurized tent in the living room into which I blow HEPA/charcoal filtered air 24-7 at 200 m^3 per hr. I used to have the filters right next to the tent which was quite noisy (dB of 40 or so). So I put the filters into another room (which is now "the equipment room") and routed the air into the tent via flexible ducts. This has eliminated the noise, but having ducts on the floor and running through doors was an issue. Plus, since I already built the clean air system for the tent, I decided to use the ducts to distribute the clean air into the other 2 rooms in the flat as well.

This is a rented flat, so I could not drill holes in the ceiling to suspend the ducts under the ceiling. I had to come up with a system which I could easily dismount and leave no trace. So I used aulminium T-slot profiles (KJN automation) which I wedged above door frames (no wall-drilling was needed), and bolted the ducts to the profile via clamps. The ducts bypass doors as shown in the picture, so each room now has it's own separate filtered air supply (which can be closed off if needed). There is no "exhaust" -- the air just leaves through whatever cracks in the walls/windows. When we move, the system should take ~2 hrs to take apart, and the profiles can be recycled for other projects (shelving unit etc).

The "equipment room" currently gets the fresh air from the outside through a cracked-open window. In the next week, I hope to make an adapter in the window to suck the air in through a separate filter, and a small heater. The equipment room is also getting its own portable air conditioner which exhausts through the same window. Hopefully, during the summer, we can run the noisy AC in the equipment room and then the filters will re-distribute the cool air to where it's needed, w/o the noise problem.

If we ever build/own a house/flat, I will look into having a proper professional false-ceiling system of rigid ducts installed.